Our Technology

Our Technology

The Center Of Power And Efficiency With Screw Compressors

Yigitsan Rotary Screw Air Comprressors stand out with their advanced design, state-of-the-art features, and cutting-edge technology. Serving as the backbone of both light and heavy industrial applications, Yigitsan Rotary Screw Air Comprressors deliver high-quality, reliable compressed air tailored to your needs.

Yigitsan Rotary Screw Air Comprressors are categorized into different segments based on product groups. They operate with high positive displacement, increasing pressure by reducing the volume of the air.

Working Principle Of Rotary Screw Air Comprressors

In Yigitsan Rotary Screw Air Comprressors, atmospheric air is drawn into the compressor via a suction valve, then filtered through the air intake filter before compression. The air is gradually compressed inside a high-tech screw unit and discharged as compressed air into the oil tank. The screw unit is driven by either an electric motor or a diesel/gasoline engine. To cool and lubricate the heat generated during compression, oil is injected into the screw unit. An air & oil separator then separates the injected oil from the compressed air. The separated oil, circulated under internal pressure, is cooled in a cooling chamber, passes through an oil filter, and returns to the injection area, maintaining a continuous circulation cycle. After being further separated from oil in the separator, compressed air passes through a minimum pressure valve and moves to the cooler. Cooling air, filtered through a dust filter, initially cools internal components and is then expelled through an aluminum block cooler, preventing damage caused by overheating.

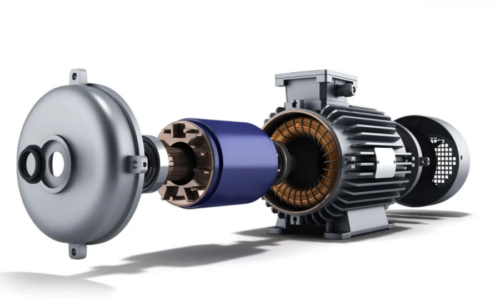

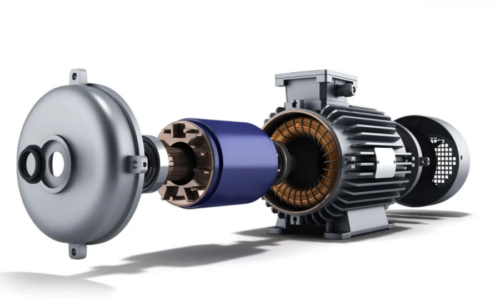

Screw Block

All Yigitsan Rotary Screw Air Comprressors are equipped with highly efficient, energy-saving screw blocks manufactured using advanced technology. These premium-quality blocks ensure maximum performance, durability, and a long service life. Depending on the application, screw blocks are powered by a V-belt drive or direct coupling to an electric or diesel/gasoline motor. Available in single- or two-stage options, they are tailored to meet specific customer requirements efficiently and effectively.

Screw Block

All Yigitsan Rotary Screw Air Comprressors are equipped with highly efficient, energy-saving screw blocks manufactured using advanced technology. These premium-quality blocks ensure maximum performance, durability, and a long service life. Depending on the application, screw blocks are powered by a V-belt drive or direct coupling to an electric or diesel/gasoline motor. Available in single- or two-stage options, they are tailored to meet specific customer requirements efficiently and effectively.

Electric Motor

Electric motors convert electrical energy into mechanical energy. Yigitsan Rotary Screw Air Comprressors are equipped with high-efficiency, CE-certified asynchronous electric motors with F-class insulation, IP55 protection, and compliant with IE3/IE4 standards. These motors are available in both cast iron and aluminum body types. Upon request, new-generation Permanent Magnet Motors (PMM) with up to IP66 protection, IE5 efficiency, and explosion-proof (Ex-proof) options are also available.

Electric Motor

Electric motors convert electrical energy into mechanical energy. Yigitsan Rotary Screw Air Comprressors are equipped with high-efficiency, CE-certified asynchronous electric motors with F-class insulation, IP55 protection, and compliant with IE3/IE4 standards. These motors are available in both cast iron and aluminum body types. Upon request, new-generation Permanent Magnet Motors (PMM) with up to IP66 protection, IE5 efficiency, and explosion-proof (Ex-proof) options are also available.

Compressor Cooling System

During compression in the Screw Block, the air and oil must be cooled in order to prevent overheating. This process is carried out by Yigitsan Compressor with high-tech fans. These fans pass the cold air taken from the outside environment through the dust filter and provide the first cooling of the equipment inside the compressor. Again, with the same fan, the hot oil passing through the radiator is cooled and returned to the system, while the pressurized hot air passing through the radiator is given to the system for the use of the facility. Thus, the equipment inside the compressor is also cooled and prevented from being damaged due to overheating. For this reason, thanks to the superior cooling system found in our Yigitsan Rotary Screw Air Comprressors, all cooling processes are provided with a powerful fan air flow, contributing to the high efficiency of the compressor. The fan motor works with temperature control in line with the parameters entered into the microprocessor, preventing unnecessary energy consumption. In addition, the cooling fans used in our Variable Speed Rotary Screw Compressors are activated when needed thanks to the inverter, and prevent excessive energy consumption. In this way, in addition to providing energy savings for your business, it also contributes to the trouble-free operation of your machines for many years.

Compressor Cooling System

During compression in the Screw Block, the air and oil must be cooled in order to prevent overheating. This process is carried out by Yigitsan Compressor with high-tech fans. These fans pass the cold air taken from the outside environment through the dust filter and provide the first cooling of the equipment inside the compressor. Again, with the same fan, the hot oil passing through the radiator is cooled and returned to the system, while the pressurized hot air passing through the radiator is given to the system for the use of the facility. Thus, the equipment inside the compressor is also cooled and prevented from being damaged due to overheating. For this reason, thanks to the superior cooling system found in our Yigitsan Rotary Screw Air Comprressors, all cooling processes are provided with a powerful fan air flow, contributing to the high efficiency of the compressor. The fan motor works with temperature control in line with the parameters entered into the microprocessor, preventing unnecessary energy consumption. In addition, the cooling fans used in our Variable Speed Rotary Screw Compressors are activated when needed thanks to the inverter, and prevent excessive energy consumption. In this way, in addition to providing energy savings for your business, it also contributes to the trouble-free operation of your machines for many years.

Microprocessor

In Yigitsan Rotary Screw Air Comprressors, a microprocessor control system with LCD screen specially designed for Yigitsan is used. Thanks to this advanced LCD microprocessor, it provides easy and fast installation and effective information display. With its advanced hardware and software technology, it automatically stops the machine in case of any malfunction. With its smart and learning software technology, it has the ability to update parameters in a way that provides maximum energy saving and optimum usage. Thanks to this microprocessor, many important parameters such as operating status, temperature and pressure levels, Oil – Air – Separator Filters and oil change times can be seen. Microprocessor control units with remote monitoring feature are fully compatible with Industry 4.0 and are designed to meet all operational needs of businesses.

Superior Features:

- Equal aging feature and Modbus Communication Support

- Adjustable Service and Part Maintenance Times

- Automatic Activation Function in Case of Power Outage

- Remote Operation Feature with Digital Input

- Last 15 Fault Records

- Standard Turkish and English interface (third-language optional)

- Adjustable Company Information Opening Screen

Microprocessor

In Yigitsan Rotary Screw Air Comprressors, a microprocessor control system with LCD screen specially designed for Yigitsan is used. Thanks to this advanced LCD microprocessor, it provides easy and fast installation and effective information display. With its advanced hardware and software technology, it automatically stops the machine in case of any malfunction. With its smart and learning software technology, it has the ability to update parameters in a way that provides maximum energy saving and optimum usage. Thanks to this microprocessor, many important parameters such as operating status, temperature and pressure levels, Oil – Air – Separator Filters and oil change times can be seen. Microprocessor control units with remote monitoring feature are fully compatible with Industry 4.0 and are designed to meet all operational needs of businesses.

Superior Features:

- Equal aging feature and Modbus Communication Support

- Adjustable Service and Part Maintenance Times

- Automatic Activation Function in Case of Power Outage

- Remote Operation Feature with Digital Input

- Last 15 Fault Records

- Standard Turkish and English interface (third-language optional)

- Adjustable Company Information Opening Screen

Inverter

Yigitsan uses inverters in its to increase energy efficiency and optimize performance. These high-tech inverters adapt the motor speed to variable load conditions, preventing unnecessary energy consumption and helping to reduce operating costs. At the same time, it minimizes mechanical wear by ensuring that the compressor operates more balancedly and for a longer time. Unlike traditional solutions, the inverter system used in Yigitsan Rotary Screw Air Comprressors uses dual IGBT output drives, and both screw and cooling fan motors are driven by independent PID control algorithms. In this way, it is fully compatible with industrial requirements and is designed to provide maximum efficiency and high performance.

Superior Features:

- Solenoid valve control

- PT100 input

- Analog inputs for internal and external pressure values

- Built-in DC reactor

- Controller (HMI) supply via driver (24VDC)

- Separate PID control for screw and fan motor

- Test mode (screw motor, fan motor rotation direction and solenoid valve on/off)

- Instantaneous Power/Pressure/Temperature curves

- Error Records (RTC)

- Sleep mode for energy saving

- Weekly/hourly work schedule

- Maintenance period settings (oil filter, air filter etc.)

- Temperature pressure protection parameters

- Optional input-based energy consumption tracking

Inverter

Yigitsan uses inverters in its to increase energy efficiency and optimize performance. These high-tech inverters adapt the motor speed to variable load conditions, preventing unnecessary energy consumption and helping to reduce operating costs. At the same time, it minimizes mechanical wear by ensuring that the compressor operates more balancedly and for a longer time. Unlike traditional solutions, the inverter system used in Yigitsan Rotary Screw Air Comprressors uses dual IGBT output drives, and both screw and cooling fan motors are driven by independent PID control algorithms. In this way, it is fully compatible with industrial requirements and is designed to provide maximum efficiency and high performance.

Superior Features:

- Solenoid valve control

- PT100 input

- Analog inputs for internal and external pressure values

- Built-in DC reactor

- Controller (HMI) supply via driver (24VDC)

- Separate PID control for screw and fan motor

- Test mode (screw motor, fan motor rotation direction and solenoid valve on/off)

- Instantaneous Power/Pressure/Temperature curves

- Error Records (RTC)

- Sleep mode for energy saving

- Weekly/hourly work schedule

- Maintenance period settings (oil filter, air filter etc.)

- Temperature pressure protection parameters

- Optional input-based energy consumption tracking

Oil Tank

The oil tank used in Yigitsan Rotary Screw Air Comprressors effectively separates the air and oil mixture coming from the compressor in two stages. The air coming out of the immersion type separator filter contains minimum oil thanks to the high efficiency separation process and this amount is at most 2-3 ppm. The lubrication process is carried out by using the pressure difference in the oil tank. This method ensures that the system requires less maintenance and at the same time increases energy efficiency. Separator tanks specially produced for Yigitsan Rotary Screw Air Comprressorss meet high quality standards and are guaranteed with CE certification. These tanks, which offer long-lasting use thanks to their durable structures, contribute to the uninterrupted and high-performance operation of the compressors.

Oil Tank

The oil tank used in Yigitsan Rotary Screw Air Comprressors effectively separates the air and oil mixture coming from the compressor in two stages. The air coming out of the immersion type separator filter contains minimum oil thanks to the high efficiency separation process and this amount is at most 2-3 ppm. The lubrication process is carried out by using the pressure difference in the oil tank. This method ensures that the system requires less maintenance and at the same time increases energy efficiency. Separator tanks specially produced for Yigitsan Rotary Screw Air Comprressorss meet high quality standards and are guaranteed with CE certification. These tanks, which offer long-lasting use thanks to their durable structures, contribute to the uninterrupted and high-performance operation of the compressors.

Heat Recovery

Energy cost reduction strategies are vital to staying competitive. An important cost reduction element that is often overlooked is the recovery of waste heat generated by compressors. The electrical energy used by an industrial air compressor is converted into hot air in the compressor and 96% of this energy can be reused at points where heat is needed in the business thanks to Heat Recovery mechanisms. Therefore, the savings potential is quite large.

Compressor heat recovery systems can heat water up to 70°C (higher temperatures are possible on request). You can recover up to 76% of the heat energy. You can use the heated water in the following main applications.

Areas of use:

- Supply to central heating systems

- Laundries

- Galvanization

- General process heat

- Wash water in the food industry

- Hot water for showers and sinks

Heat Recovery

Energy cost reduction strategies are vital to staying competitive. An important cost reduction element that is often overlooked is the recovery of waste heat generated by compressors. The electrical energy used by an industrial air compressor is converted into hot air in the compressor and 96% of this energy can be reused at points where heat is needed in the business thanks to Heat Recovery mechanisms. Therefore, the savings potential is quite large.

Compressor heat recovery systems can heat water up to 70°C (higher temperatures are possible on request). You can recover up to 76% of the heat energy. You can use the heated water in the following main applications.

Areas of use:

- Supply to central heating systems

- Laundries

- Galvanization

- General process heat

- Wash water in the food industry

- Hot water for showers and sinks